By Natasha Romough,

Director of Marketing and Communications, CHBA

Three years ago, the Canadian Home Builders’ Association (CHBA) and several leading members from across the country began working on an exciting new Net Zero initiative for multi-unit residential buildings (MURBs), in partnership with Natural Resources Canada.

Lowrise (part 9) MURBs are an increasingly common housing type in many communities across the country. They allow for densification while still being a desirable ground-oriented option that many buyers are looking for. The MURBs initiative is advancing solutions, technologies and approaches to building Net Zero Energy Ready and Net Zero Energy multi-unit residential buildings (MURBs), with the goal of producing homes that are affordable, replicable and appealing to Canadians.

The objective of the initiative is to validate the use of pre-fabrication (panelization and modular construction) and integrated mechanical system technologies, design and practices on Net Zero Energy Ready and Net Zero Energy MURBs to optimize energy efficient performance, increase construction productivity, shorten construction schedules and reduce costs.

At the heart of the initiative is six builders from British Columbia, Alberta, Saskatchewan and Ontario. All of them agreed to build a lowrise MURB for purely residential occupancy, and they joined the initiative in its early days, during the planning stage.

Marie Hanchet, CHBA project manager for the MURBs initiative, helped put together teams of builders, manufacturers and experts in building science, pre-fabrication, insulation, windows, mechanicals and renewable energy. Together, they met regularly to optimize their designs before construction started.

It’s a project that Hanchet has poured her all into over the last three years. “Working with this collaborative group of builders through the pandemic meant frequent adjustments to project plans and milestone events, but it was all in an eff ort to identify solutions we can share broadly with the industry; and we’re almost ready to do that,” she says.

Four stages

The Net Zero MURBs project is comprised of four stages: Planning, building, analyzing and sharing. The planning stage finished a couple years ago for all the builders. It consisted of collaboration among builders, manufacturers, and building science experts to determine the optimal design specs and materials.

The process provided some key takeaways for builders, one of which applied to most of their builds. “During the energy cost optimization exercises,” Hanchet shares, “five of the six builders moved away from drain water heat recovery installations that they had previously used, in favour of more cost-effective renewable energy generation.”

In the second stage, the participating builders construct the homes. The six participating builders are at various points of completion, with three projects already occupied. All of the projects are a minimum of two vertically stacked units and are a minimum of two storeys above finished grade. They also were all required to include panelization and/or modular construction.

The third stage is analysis of the actual overall cost savings and productivity gains (compared to the code and current practice in each region) for each build to determine the average savings and assess what level of savings are achievable on a mass scale. An example is analysis that was performed and detailed on how to reduce both construction and operation costs on solar array configurations when looking at multiple units in a single building. (Analysis of two configurations concluded that there is more than 11 per cent savings in a single point of connection with submetering, which amounts to more than $35,000 in savings for a 12-unit Net Zero MURB. More details can be found at chba.ca/nzmurbs.)

In the fourth stage, knowledge learned from the initiative will be disseminated across the country, and will include a capacity-building education program to bring the learnings to the mass market.

Landmark Homes

Haitao Yu has been leading Landmark Homes‘ R&D department since 2010. He began his career as a structural and on-site project engineer in China, before moving to Canada in 2003 and completing a PhD in Construction Engineering and Management at the University of Alberta. He shares Landmark’s passion for building highly efficient homes using prefabrication due to the positive implications for future generations. Yu believes that “humankind should act today for the future of our children,” and that the knowledge learned coming out of initiatives like the MURBs project aligns with that goal.

Landmark built its fi rst Net Zero home in Calgary in 2012, and has constructed 30 more since then, in addition to 70 Net Zero-Ready homes. The company’s MURBs built for this project represent the first time it has done stacked Net Zero-Ready towns (until now, it focused on single-family homes and townhomes). Comprising 11 units, the building was finished earlier this year, though the air source heat pump wasn’t able to be installed until the end of August, followed by the blower door test and the energy advisor’s final inspection in early September.

One of the unique elements of this project is Landmark’s use of new technology for the heating system, which they developed with a local HVAC manufacturer.

“Due to the high carbon intensity of Alberta’s electricity grid and the big drop in the efficiency of air source heat pumps in the harsh Alberta weather, the project adopted dual fuel hybrid heating systems with high-velocity air delivery to minimize greenhouse gas emissions in home operation while improving the comfort of occupants,” says Yu. A small roof-top solar PV system (2.25 to 2.7 kW) was installed on each of the MURB units.

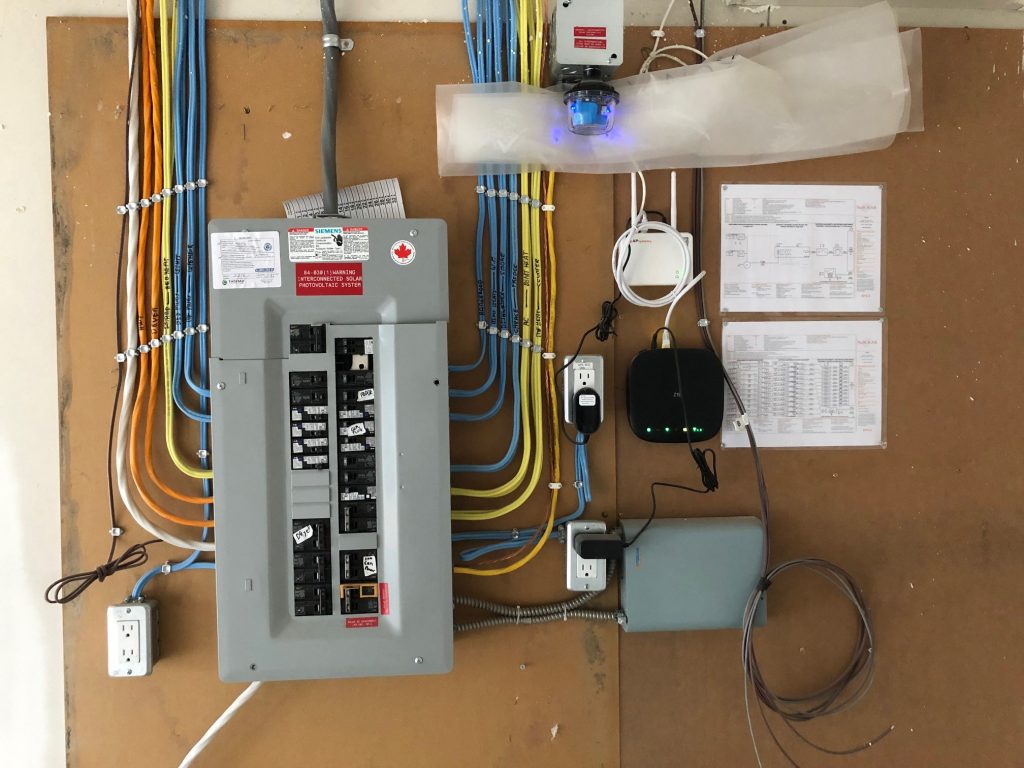

Each of the MURBs involved in the project will be equipped with an energy monitoring system, which will provide a minute-by-minute energy profile. Current energy modelling (such as HOT2000) provides only monthly and annual energy consumption, but the data from the energy monitoring system “will indicate when the building’s highest energy demand is,” Yu explains, “so that service infrastructure can be right-sized to meet that demand in the future.”

Supported by the consultants of CHBA Net Zero MURBs initiative, a research team from the University of Alberta installed energy monitoring systems in the units that are part of the project for CHBA’s MURBs initiative, as well as in the block next to it, which was built with Landmark’s standard specifications. The university will collect the data, perform analyses, and develop an energy profile simulation model for peak loads of highly energy efficient MURB communities.

In addition to peak loads, the performance of the new heating system, as well as the interaction between home energy consumption and PV generation, will be analysed.

Yu says he is eager to get started on that data collection after a year of project delays. Because this project is purpose-built rental with low margins, the high lumber prices during the pandemic resulted in holding off on construction for six months until lumber prices started to stabilize and come back down a little. Using a new heating system also added a little more time to the project, because Landmark’s usual trades professionals needed to be trained, with the help of the manufacturers, on how to properly do the installation. The air source heat pump delivery was delayed by about six months, and it finally arrived in winter when installation isn’t possible, further pushing back project completion.

The delays, however, haven’t lessened anyone’s enthusiasm. “Landmark has been part of CHBA’s Net Zero Council since the beginning and this project was perfect for us since we build prefab and Net Zero,” says Yu. “We do want to use CHBA as a platform and work with other builders who have the same mindset and goals. This program is a good way to work with others and see what they’re doing. We can learn from others and others can learn from us.”

Zirnhelt Timber Frames

Meanwhile, another project is finishing up in Williams Lake First Nations in British Columbia. The build is two stacked 800-sq.-ft. apartments, designed as purpose-built rentals with specific occupants in mind, including one who uses a wheelchair.

Sam Zirnhelt started his business sawmilling, and 17 years ago started working as a general contractor with the goal of making better use of the timber they were harvesting by creating the most energy efficient homes they could. Before that, he worked as forester, land use planner and in economic development after doing his undergraduate with the Maori in New Zealand. Community-oriented projects are something he still very much enjoys doing, with about half Zirnhelt’s projects consisting of community/cultural buildings (daycares, health centres, cultural centres), the other half residential, mostly single-family homes.

While this is Zirnhelt’s first MURB, panelization has been part of the company’s process for at least 12 years.

“The way we build the envelope is so intensive on the tools, that you wouldn’t want to use them in an outdoor environment,” he says. The company begins by selecting timber from nearby community forests, which it custom-mills – a step Zirnhelt says is critical to controlling the timing and quality of construction. The walls are pre-built in Zirnhelt’s shop, with the siding and windows pre-installed, and the insulation and exterior complete. The walls are then craned into place. This MURB project was built with four pieces.

Building a wheelchair-accessible suite was a new challenge for Zirnhelt. The company worked with local professionals to work out what would be needed for appliances, cabinets and bathroom fixtures – and then formulated its own integrated design process. Zirnhelt says he was surprised to learn that approximately 20 per cent more room was needed to accommodate a wheelchair.

It was the mechanical system that proved the most challenging, however. Net Zero homes need only small units, and the options are few. Zirnhelt ended up selecting a ductless mini split system by Panasonic that is compatible with the cold climate in Williams Lake. These heat pumps are due to arrive in early October.

Zirnhelt joined CHBA after attending a Local Energy Efficiency Partnership (LEEP) session and seeing the value of connecting with others who were also pursuing high-efficiency homes. “If I’m going to spend my life building, I want to be on the cutting edge,” he says. He participated in the LEEP process while building his first Net Zero building: A six-unit treatment centre. He’s since been part of several LEEP presentations.

“We need to focus on energy efficiency, but also on durability and how to reduce the embodied energy in what build as well,” says Zirnhelt. “And we should be building something that’s beautiful so that people want to take care of it and have it last.”

Sharing lessons learned

With nearly four out of six MURBs in the initiative complete, next comes analysis of data, including occupant data. It’s a stage that those passionate about energy efficiency are looking forward to, since very little data has been collected to date.

“The team is extremely eager to share results of the project, but with that will mean a close-out to the official project and strong relationships that were developed in a humble group,” Hanchet says. “We learned from one another, asked so many questions, and each participant brought a different lens and set of expertise to the work of designing and construction multifamily housing that supports the triple bottom line: People, planet, profit.”

Though the MURBs initiative will eventually wrap up, the lessons learned from it will be shared across the country and used for years to come. And members keen on voluntarily achieving Net Zero will continue to evolve CHBA’s Net Zero Council, and through it, its Net Zero Home Labelling Program, which has labelled more than 1,000 new homes and renovations since its pilot in 2015.

For more information on the CHBA Net Zero MURBs Initiative, visit chba.ca/nzmurbs.