By Natasha Rombough, Director of Marketing & Communications, CHBA

There’s a new development in southeast Calgary that’s bringing together high-performance modular construction and energy-efficient design.

Emerge Seton Towns is Avalon Master Builder’s newest purpose-built rental community, ideally situated within walking distance to major amenities, including healthcare, shopping, the YMCA, transit and an upcoming 6.4-hectare park. It will feature 46 stacked townhomes, with two thoughtfully designed home types: A level-living two-bedroom, one-bath home (566 to 577 sq. ft.), starting at $1,295/month, and a spacious three-bedroom, 2.5-bath, two-storey home (1,232 to 1,239 sq. ft.), starting at $1,895/month (utilities not included in either). All homes will be qualified through the CHBA Net Zero Home Labelling Program, which means those utilities bills should be very manageable depending on occupants’ usage.

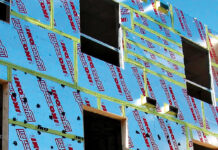

Chris Williams is president of Avalon Master Builder. He’s well-versed in Net Zero construction and was a founding member of CHBA’s Net Zero Energy Housing Council back in 2014, and still sits on its Management Committee. Emerge Seton is the second townhome project that Avalon has built that utilized volumetric modular construction. “We chose to use modular construction for Emerge Seton as we believe this is the future of construction – the ability to control the variables inside of a factory is the perfect scenario for high performance and durable housing,” Williams says. “We also wanted to hone our modular construction skills close to home (in Calgary), as we prepare our offering for communities that have more challenging site conditions or smaller labour forces.”

Developing with a modular-first approach

Incorporating factory-built construction requires taking a modular-first approach to design. Avalon has been building traditionally for 42 years, and its procedures did not align with the needs of modular, which requires more pre-planning to be successful. “Many other construction solutions allow you to start with architectural design, then pivot to alternative construction practices. It can be very difficult to use modular construction if the architectural design does not plan for modular,” Williams says.

To help Avalon design for modular, the company began the project by partnering with fellow CHBA members Big Block Construction and Gravity Architecture. Avalon also included local building officials early on to ensure the project efficiently navigated the complexities of CSA scope lines and local building authority interpretations.

From that process, the company had its architectural plans, which modular factory builder Grandeur Housing – yet another CHBA member, featured on page 12 – used to create a set of shop drawings.

“Upon release of permitting, it was a race for Avalon to complete the undergrounds, surface works and foundations installs before the modular units were ready to ship,” says Williams. “Big Block Construction supervised the modular production, and began to prepare the logistics of shipping, staging, craning and completions of the buildings. The final stages by Avalon included further civil surface works and landscaping.”

From a land development perspective, Williams says modular construction changes things in a big way, especially for nearby residents. “In a perfect world, we would complete all civil works, all basements/foundations, much of the curvaceous improvements, and then the modules would just start arriving. The neighbouring homes are only disturbed for a couple of months, rather than for a couple of years.”

Timeline gains depend on coordinated approach

Theoretically, developments using factory-built construction should see significant timeline improvements. The units themselves can be built in a fraction of the time, but other factors outside of the developer’s control are at play, including permitting and servicing. For Emerge Seton, delays in permitting resulted in the factory being held up for many weeks, and when all four buildings were craned in place, they sat without electricity for many months. “Although on this project the overall project timeline was much the same as tradition construction,” Williams says, “the learns on our approach were invaluable.”

Challenges for modular developments

Williams notes that financing was a hurdle, since traditional financing terms expect product on site prior to funding. For Emerge Seton, that meant large deposits were required for product that may not be installed for months.

Permitting and inspections were also challenging. “We believe that we have navigated the permitting requirements for Calgary, and in fact had a much smoother experience with a more recent project in Calgary, but the assumption that CSA created a clear scope line of authority having jurisdiction is a very unsafe assumption,” Williams warns. The experience with inspections was similar.

More modular in Avalon’s future

Going modular has been a learning curve for Avalon, and the company is just getting started developing communities with factory-built homes. Avalon has two upcoming modular projects being built in partnership with Big Block Construction: A building in Belmont (Calgary), and a 120-unit Net Zero townhome project in Canmore, Alta. Despite the changes needed to procedures and the challenges encountered, Williams sees the benefits of modular construction and is enthusiastic about applying the lessons Avalon learned: “Our experience in preplanning design, financing and the local authority having jurisdiction partnership have already been applied and are making a difference.”